Customer Services

Copyright © 2025 Desertcart Holdings Limited

⚙️ Power your precision with smart, silent control—because your motor deserves the best.

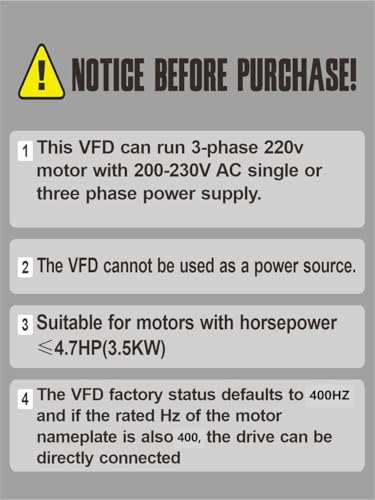

The HY Series VFD Converter transforms 220V single-phase input into stable 220V three-phase output, delivering 4kW (5HP) power to industrial motors. Featuring RS-485 communication, remote speed control, low noise, and CE certification, it’s engineered for reliable, efficient motor speed management in professional settings.

| ASIN | B07HDYX25C |

| Batteries required | No |

| Customer Reviews | 4.2 4.2 out of 5 stars (341) |

| Is Discontinued By Manufacturer | No |

| Item Weight | 6.76 pounds |

| Item model number | HY04D023B |

| Manufacturer | Huanyang Electrical |

| Product Dimensions | 8.7 x 6.7 x 5.9 inches |

P**H

6 Years of flawless 24/7 Operation

I have 4 of these operating pumps 24/7 365 since 2020. They are in a hot environment, so I have a 4" computer style fan laying on top of each controller drawing up to assist with heat management. The internal fan is probably not up to this task once the heat sinks become dirty after a year or two. Heat kills silicon, so it is well worth the extra $10 investment for an external fan. I am using external control of speed and also using another input as a safety fallback to keep the pumps idling at 20hz in the case of a blockage or other water issue. Make sure they are mounted vertically (as shown in the product photo) for proper airflow.

G**X

Works well, quiet and smooth startup

Works well on Bridgeport clone. I have it locked to 60hz because I’m using a Varispeed. The motor doesn’t see designed to cool at low speeds so I won’t be using variable frequency until I replace w good Baldor

J**H

Get a wider range of speeds on your drill press.

This unit was installed on my 60 year old Craftsman drill press. The drill press's spindle would never run slow enough for large drills or several other applications. I replaced the original single speed motor with a three phase motor and powered it through this VFD drive. I now have an infinite range of speeds from barely turning up to very high rpm's. Torque is surprisingly high, even at very low speeds.

L**T

Not plug and play. Not happy. Had it for over 2 years and still can not make it work

I bought this in 2020 it is now 2022 and I still do not have it working, I have never been able to get it to work, Input voltage is 220 and output voltage is 0 . My gripe is if they are going to sell it to everybody then it should be user friendly to anyone or at least Warn the people doing the purchasing of the difficulty in programing one. if they want to sell to Americans, it should be simple English and easy access to American support after the sell.

H**Y

Cheap junk, but working well

This is a pretty solid inverter so far for running my three-phase lathe off of single phase 240 volt. I had to get a seven and a horsepower vfd so that I could run a 3 horsepower lathe. This drive still can't start the motor at high speed without a 12 second ramp time. This manufacturer overrates their Drive by at least half to two-thirds. not a bad buy for the money, just make sure you grotesquely oversize the drive you think you're going to need for your application in order to be reliable. There's a fair amount of support for these drives on the interweb, but several of the popular CNC forums have banned their discussion as a topic, because so many people have had bad luck with them. I must have got one that was built on a Tuesday morning because this one seems to hum right along and lived a fairly long life in my welding shop. This particular device runs at Wheat State welding LLC in Derby Kansas and is installed on a three-horsepower 15x60 lathe. 6/27/23: 3 1/2 years later this drive is humming right along. I haven't had a single issue. I have a smaller one as a cnc router spindle drive that works good to. 4

J**Y

Works great but no RS485 documentation

After my Automation Direct VFD failed, I decided to try a Chinese brand to run my 2hp pool pump. After reading reviews and applying logic, I decided to get a 5hp VFD. I made a custom control panel with some automation for my AD unit and wanted to use it for this unit. The control is over RS485. There is no documentation on the RS485 protocol - none in the manual or on the manufacturer's website. I found a few commands on a woodworking website, enough to get me by. This unit has some nice features that the AD didn't have such as auto load detect which only delivers enough power to maintain frequency.

L**E

Keep it dust-free and it will last a long time

I used this for my 2 kW motor on a belt sander and it works great. Relatively easy to program too. You can disconnect the face controls and use a long ribbon cable to keep the VFD in a cabinet and have the controls outside in a 3D printed housing. Still, it isn't immune to dust. Make sure to blow it out every so often with an air compressor. The first one lasted 5 years and would have lasted longer if I took care of it. I got another one and will keep it maintained.

J**F

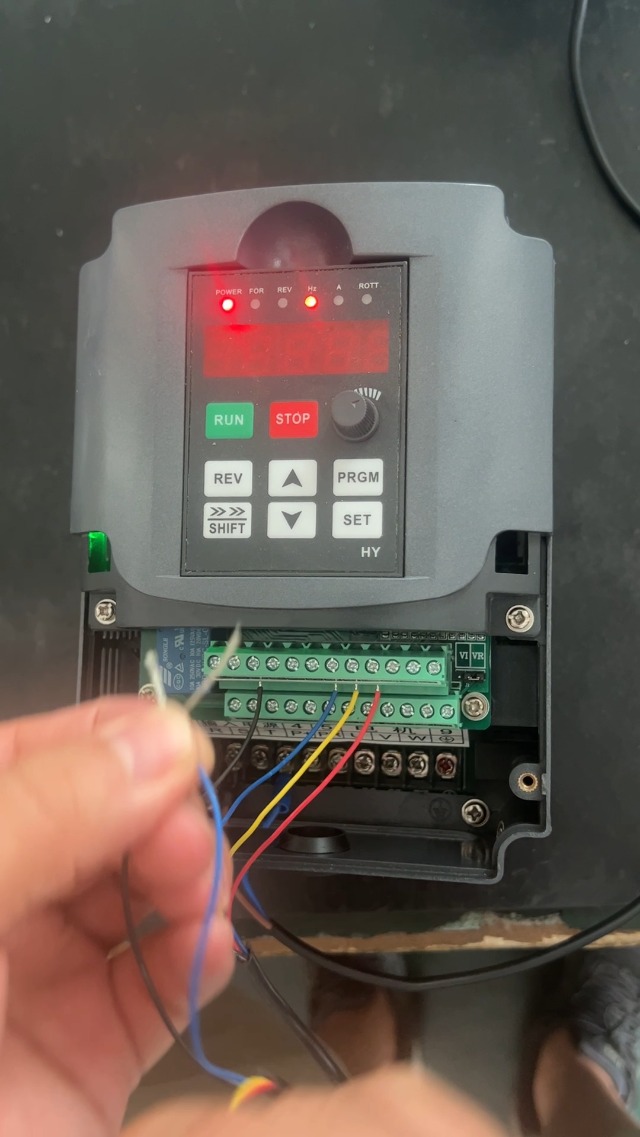

Has been great. Was worried about programming, but was easy enough

I was worried about programming this, but it wasn't hard at all. The manual is pretty clear. I did have a single point of misunderstanding but support answered it quickly. I used remote switches on my mill to go forward,reverse,and stop... And I put a potentiometer atop the box. I mis wired the potentiometer , and tech explained the correct wiring and got me going. Very happy with it so far as it has worked great, and my milling is much more accurate with speed control , I can power tap without my tapping head. Awesome, wish I had done this much sooner.

K**E

First time setup this make of VFD, it is easy to to set up and work great. Will use this make next time.

A**D

HUANYANG VFD HY01D523B 1ph in 3ph out 0-220 vac 1.5Kw (2hp) 0.50hz- 400.0hz Output current 7.0 A Motor Leeson C184T11FB10C 3ph 208-230 v 60 Hz 2 Hp (1,5kw) FLA 7.2 SFA 7.8 Eff. 86.5% 6 Poles Notes: VFD Settings varies from a company to another Steps for programming the parameters. 1) Press “Program” 2) Press “Up” or “Down” arrows to get to the parameter you want. 3) Press “Set” to select the parameter for editing. 4) Press “Up” or “Down” arrows to enter the setting you want. 5) Press “Set” to lock in the new parameter value *Note: The “Shift” button changes the input position from right to left across the display. Parameter Value My Explanation PD000 0 0 = Allows VFD parameters to be adjusted 1 = Prevents VFD parameters from being adjusted PD013 0 8 = Reset VFD to factory settings (if necessary) PD001 1 0 = Start/Stop motor by buttons on the front of the drive. 1 = Start/Stop motor by external switch 2 = Start/Stop motor by computer communication port" PD002 1 0 = Motor Speed adjusted by buttons on the front of the drive 1 = Motor Speed adjusted by potentiometer (Onboard or external, jumper on “VI” for external or “VR” for onboard) 2 = Motor Speed adjusted via computer communication port" PD005 60 The maximum frequency that the drive will send to the motor. PD004 60 Rated frequency of the motor as listed on the motor's nameplate. PD003 60 The frequency (speed) the motor starts off at when PD002 is set to 0 . PD008 220 Rated voltage of the motor as listed on the motor's nameplate PD014 2.0 Time in seconds for motor to accelerate to full speed. PD015 2.0 Time in seconds for motor to decelerate to complete stop. PD023 1 0 = Reverse motor rotation not allowed. 1 = Reverse motor rotation is allowed. PD070 0 0 = 0-10V for external potentiometer Ref PD002 PD072 60 Higher analog frequency Same as PD005 (Factory set a 400hz not 50hz) PD141 220 Rated voltage of the motor as listed on the motor's nameplate. PD142 7 Set it to VFD max rating. F.L.A. (Full load amp) rating of the motor as listed on the motor's nameplate. PD143 6 Number of poles = 120(f)/n where f = motor's rated operating frequency (60Hz in the USA) and n = motor's rated RPM on the nameplate. 120 factor x 60 HZ divide by 1165 rpm = 6,180 rounded to 6 PD144 1165 Rated RPM of the motor as listed on the motor's nameplate.

J**S

The item come faulty however, no fault of the sellers. I just got unlucky. However, communication was 5* with the seller & a refund is processing. Thank you so much

R**T

Je ne m'attendais pas à recevoir cet article si rapidement. Bravo. Paquet bien emballé, bonne instruction, il suffit de bien lire tout le document avant d'entreprendre les connections. Très satisfait

P**E

Cnc

Trustpilot

2 months ago

3 weeks ago