Deliver to Cyprus

IFor best experience Get the App

⚙️ Elevate your CNC game with power, precision, and cool confidence!

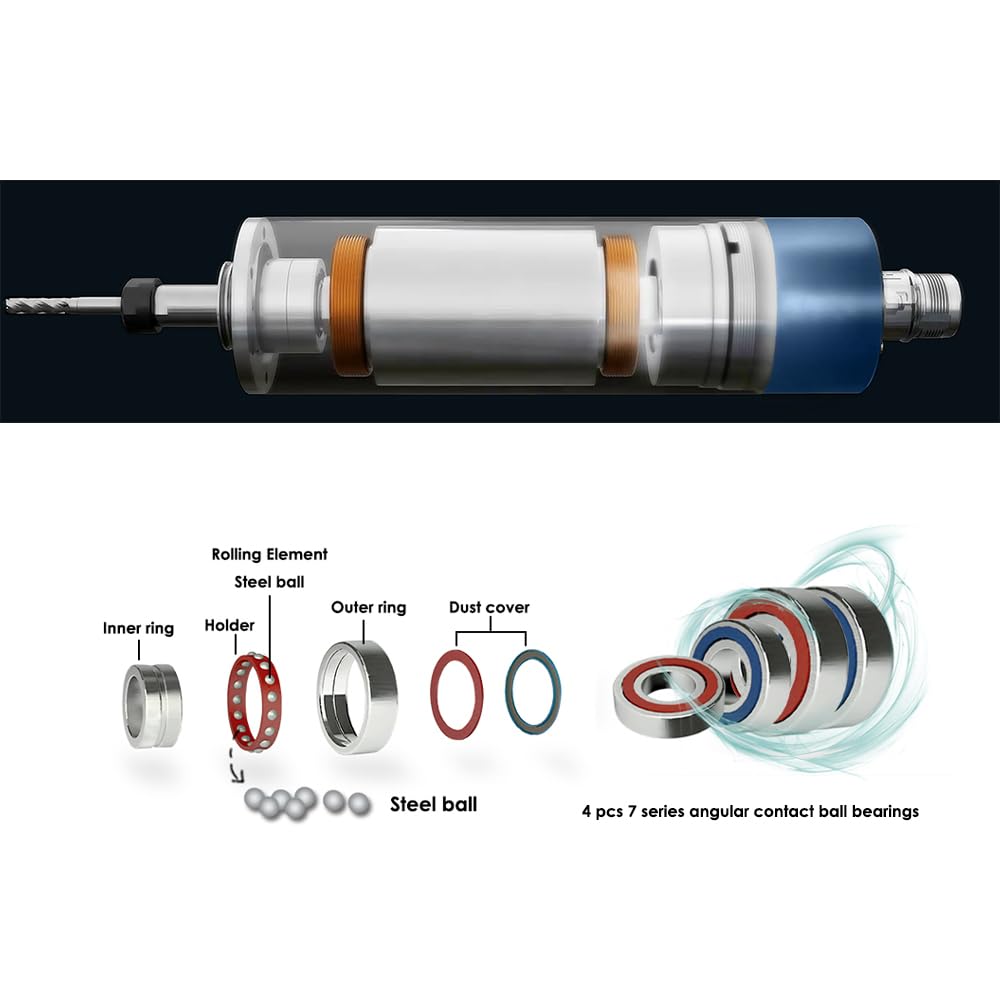

This 1.5KW ER11 D65 110V air-cooled spindle motor kit from G-Penny Machine combines high power output with precision engineering, featuring advanced angular contact bearings and a dedicated 110V QL inverter. Designed for professional CNC setups, it ensures reliable, cool operation and easy installation with included mounting bracket and optimized grounding.

| Manufacturer | G-Penny Machine |

| Item Weight | 13.92 pounds |

| Package Dimensions | 15.09 x 12 x 7.09 inches |

| Country of Origin | China |

| Item model number | 1.5KW ER11 D65 110V |

| Power Source | ac |

| Included Components | 1.5KW ER11 D65 110V Air cooled spindle motor + 1.5KW 110V QL Inverter + 65mm Bracket |

| Batteries Required? | No |

J**S

Upgrading from a router? This is not as powerful as a Makita trim router

I bought this as an attempt to upgrade the trim router on my V1 Engineering LowRider 3 CNC machine. My goals were to get a quieter machine, software controlled speed, and better dust collection.This VFD and Spindle come with 1/8" and 1/4" collets. Everything was packaged very well. You will need to get a cable to connect the spindle to the VFD. I went with a 16AWG 16/4 core shielded wire (https://www.amazon.com/dp/B0D2HMR9FR) and used the included connector for the spindle side.For the VFD side, you will need a cable to power the VFD. I used a 14AWG computer cord, and cut the end off. I used crimped terminal connectors to get a good connection.For spindle control, you have a couple options. You can control everything from the VFD, or you can connect with your CNC control board. To connect to the control board, you need 0-5v or 0-10v, usually done with PWM. Alternatively, and probably better is if you have a board that supports RS485.Spindles need to be broken in before you can operate them. I followed these increments and changed every 20 minutes.6000 rpm for 20-30 min - 100hz9000 rpm for 20-30 min - 150hz2000 rpm for 20-30 min - 200hz18000 rpm for 20-30 min - 300hz24000 rpm for 20-30 min - 400hz (max speed)The first time I tried to make a cut, my spindle was spinning in the opposite direction. If this happens, you can change any two wires going to the spindle (U,V,W) or you can push and hold the direction button on the VFD.This spindle is much heavier than the Makita. My steppers were running a little hotter, but still within spec.The power difference was evident when I was using a bowl bit. I made some test pockets in hard maple and stalled the router bit completely. That never happened on the Makita.To summarize -- It is more quiet, under no load. Maybe even with smaller bits. Most of the noise when using a CNC is the cutting noise, which is the same with a spindle. The vacumn or dust collection is also still loud.- Speed control is nice, but I wasn't able to configure with my specific controller. I still get the 1-6 dial on the Makita trim router.- I thought dust collection would be better because the spindle cooling fan is at the top. That didn't seem to make a difference except in profiling.- If you are looking for more power than a trim router, I think you would need a 2.2KW spindle.

D**L

2/1/25 UPDATE

Purchased this VFD spindle for my Genmitsu ProverXL 4030. I was so tired of listening to a trim router screaming at me for the duration of a long job. This spindle is so much quieter. And I'm tired of replacing trim router brushes every 100-150 hours of operation. Other reviews mention this spindle bogging down or stalling during surfacing jobs, I can tell you that's a very subjective claim. If you use a speed and feed rate appropriate for the material being machined, then you should have no problem. I routinely surface hardwood cutting boards made from bubinga and goncalo and I run a 25.4 mm dia surfacing bit. I run that bit at 15-20 mm/sec feed and cut at a depth of .5-1mm and have zero issues with this spindle. For my needs, this spindle has run like a champ and I no longer have to have hearing protection unless I've got other machines running. Don't expect to install this VFD spindle using just the included instruction manual. Watch a few YT tutorials and your installation should be fairly easy. This spindle far exceeds the capabilities of using a trim router in your cnc router machine. I cannot speak to it's durability as I've only got about 25 hours on it, but I feel safe to say that I'd purchase this again. One thing to note, the included 65mm mount is a hunk of metal. Plan on buying a 65mm mount designed for your machine. The included mount weighs way more than I wanted to hang on my Z axis.2/1/25 UPDATE:I now have over 250 hours on this VFD and it has run perfectly. The controller takes a little tweaking to get an accurate RPM but theres no shortage of YT videos showing how to do that. With as much work as this spindle has completed, often running a 1" surfacing endmill, I would buy it again in a heartbeat. If you are on the fence about converting your CNC from a trim router to a VFD, this one pretty mucks kicks butt. I monitor temperature of my bits and the spindle and this motor rarely exceeds the ambient temperature. FIVE STARS !!

Trustpilot

3 weeks ago

1 day ago