Customer Services

Copyright © 2025 Desertcart Holdings Limited

Desert Online General Trading LLC

Dubai, United Arab Emirates

🔄 Switch Smart, Stay Powered: The Ultimate 3-Position Selector

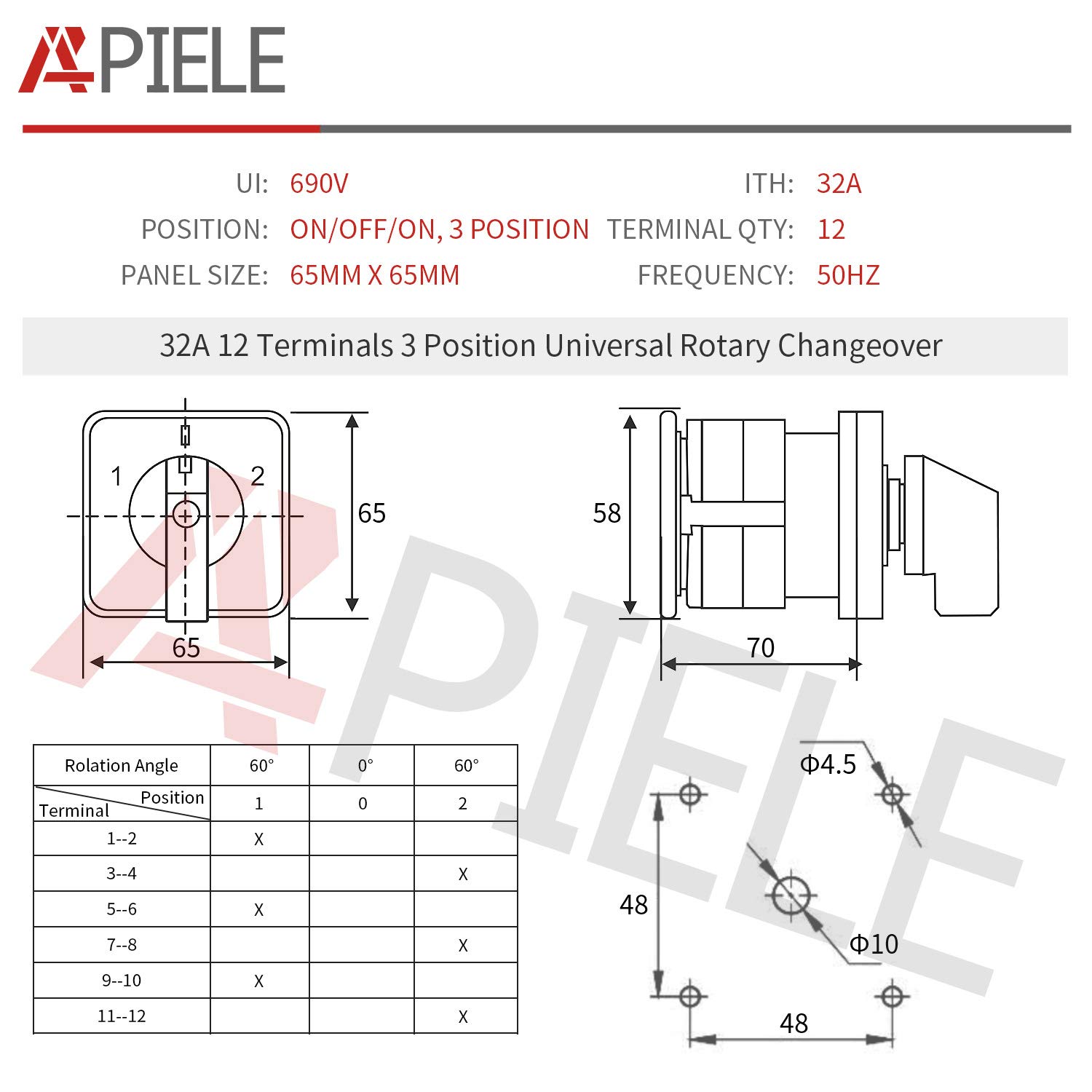

The APIELE LW28 3-Position Changeover Selector Switch is a robust, universal rotary cam switch designed for 3-phase electrical systems. Rated at 32A and 690V, it features 12 terminals and a compact 48x48mm panel size. Constructed with flame retardant, high-temperature resistant PC material and premium copper contacts with silver alloy points, it ensures durability and reliable conductivity. Engineered for long-lasting performance, it promises a minimum 3-year lifespan under normal use.

J**E

Very Nice, Well Made Switch - But, some out of box issues

Please see additional comments concerning reliability at the end of the review.This is a solid multi-pole transfer switch. I am actually using it to switch a power line filter in and out of the primary shore power circuit in a camper. The filter unexpectedly trips some ground fault breakers. So, there are instances when the filter needs to be bypassed. Since both sides of the filter need to be removed from the circuit this switch allows an elegant solution.You are getting a lot of switch for your money here. It seems well made and is easy to install. As with many Chinese made items, especially those selling at low prices as compared to market, it lacks any instructions or schematics at all. So, you must rely on those you find online or in the product's ad. In this case, as the title of the review alluded, the wiring diagram/switch schematic shown in the product photos is incorrect, depicting a 16 pole switch, not the 12 pole switch you are buying. The description of the product was correct. But, I needed the 16 Pole, but with four poles unused in my design, not in linear pairs. I initially ordered the wrong switch as I designed my circuit based on the schematic provided. It's my mistake, but don't make it yourself. Several suggestions I would make to the seller would be to show the width of terminals which can be used and size of the securing terminal screws. I am not a fan of poking high amperage wires under a securing plate and tightening them into place. I'd prefer to use spade or loop lugs for a more secure connection. To use those it would be useful to have the this information added to the dimensional diagram. A mounting template would also be useful, as to mount the switch neatly you will need to make one yourself.Additional comments added after several months of use:My transfer function ceased to work in one of the positions despite having been tested good before installation. Testing revealed that one of the selected closed pole positions was not conducting. As I had two spare poles for that side, I moved the function to a spare and was back in business. However, I initiated a return to swap out the "faulty" switch. I ordered this one from another seller, though it was obviously the same Chinese switch. My initial seller was out of stock. When it arrived, before installation, I tested all of the poles. One was not conducting. Playing with the switch I found that if I switched it back and forth a number of times it started working and seemingly kept working after that. So, I went back to my installed "bad switch." I did the same, switching it back and forth a number of times. The "bad" pole started working. Because this seems to be a peculiaritity of this switch I decided to keep the installed switch, functioning on the backup pole. My bad pe now working, I still have a spare. It is a very complicated installation/wiring and a real job to change out, so, without any advantage I'll leave well enough alone.I do not know why I have encountered the intermittent pole issue. Two switches out of the box like this seems to be a trend. I still think this switch is a good value, considering the very low cost, if it will function reliably after it's "loosened up." But, we shall see.

R**Y

It works!

The switch works as described. I needed it to switch between two 220 volt devices. It worked perfectly.

A**K

Looks like it’ll work.

This is a little deep to fit in a normal double gang box. The switch it self is medium quality. Definitely good enough but not ‘industrial quality’ by any stretch.

P**2

Great Switch, well made!

I was having trouble trying to figure out what went were until I read the instructions (that does help sometimes) then everything fell into place and it was very easy to see what went where and why. I wish that I had known about these switches long ago, they are now number 1 on my list.

E**A

Entrega inmediata

Entrega inmediata y calidad superior

S**E

Solid switch with easy installation if you understqand electrics.

Reliable so far. Used as a selector for shore power vs generator power in a small RV conversion.

M**K

Be careful- mounting nut might fall out of shaft

The switch we received worked just fine for our application; using it as a 20A, SP3T transfer switch; mounted to the side of a 3R box, with a WP cover over the exposed knob area.Will I buy it again? Good price, but…The item comes with no instructions at all.When ready to mount the switch to your panel, the first thing everyone has to do is- separate the knob and square subplates from the assembly, by first removing the screw from the knob.Be very careful when you do this, as a very small nut (under 4-40 in size) will most likely fall out and land somewhere in your work area.What is NOT shown or explained anywhere at all is that the main knob is held in place by a screw that threads into a plastic sleeve and that sleeve “squeezes against” the plastic shaft when the knob screw is tightened; holding both the knob & sleeve in place on the shaft. Dropped (vertically) down inside that sleeve is a very small steel nut, that is engaged (and held in place) when the knob screw is tightened. When the screw is taken out, to remove the knob, there is really nothing else that holds the steel nut in place. (The nut slides into a slot on the side of the sleeve and it comes out just as easily as it goes in.) Expect the nut to fall out someplace; hopefully someplace where you can retrieve it. Once I figured out how this worked, I just epoxied the nut into place inside the sleeve so, when I did the final install on a jobsite, I wouldn’t risk losing the nut in the dirt, or someplace else. The nut is probably 2.5mm; it is not a 4-40, but only slightly smaller.My suggestions-1. Disassemble the parts first in a shop, on a clean workbench, with good lighting. 2. Epoxy the nut into the sleeve, so it won’t fall out when servicing later on. 3. Continuity test the switch for integrity and use a small (silver color) Sharpie Pen to note the terminal positions & mark how they interconnect.Doing all this in advance will just make the install go a lot smoother.

M**E

A wiring challenge but works great

I purchased this 16 terminal 3-position switch to replace one on an older Chinese mill/drill. With sixteen terminals plus additional jumper wires between some of them, careful marking of the wires is very necessary. I had no issues with the quality of this switch and it does its job just fine. Good value for the money. Also note this was the 15A version I got after returning the 63A version because a) tge 63A came broken (why Amazon insists on pinching pennies by using bags instead of boxes for a primarily plastic item like this is ridiculous to me) and b) the 63A is a very large switch. Be sure to check the dimensions.

Trustpilot

2 weeks ago

2 weeks ago