🚀 Elevate Your Craft with Unyielding Support!

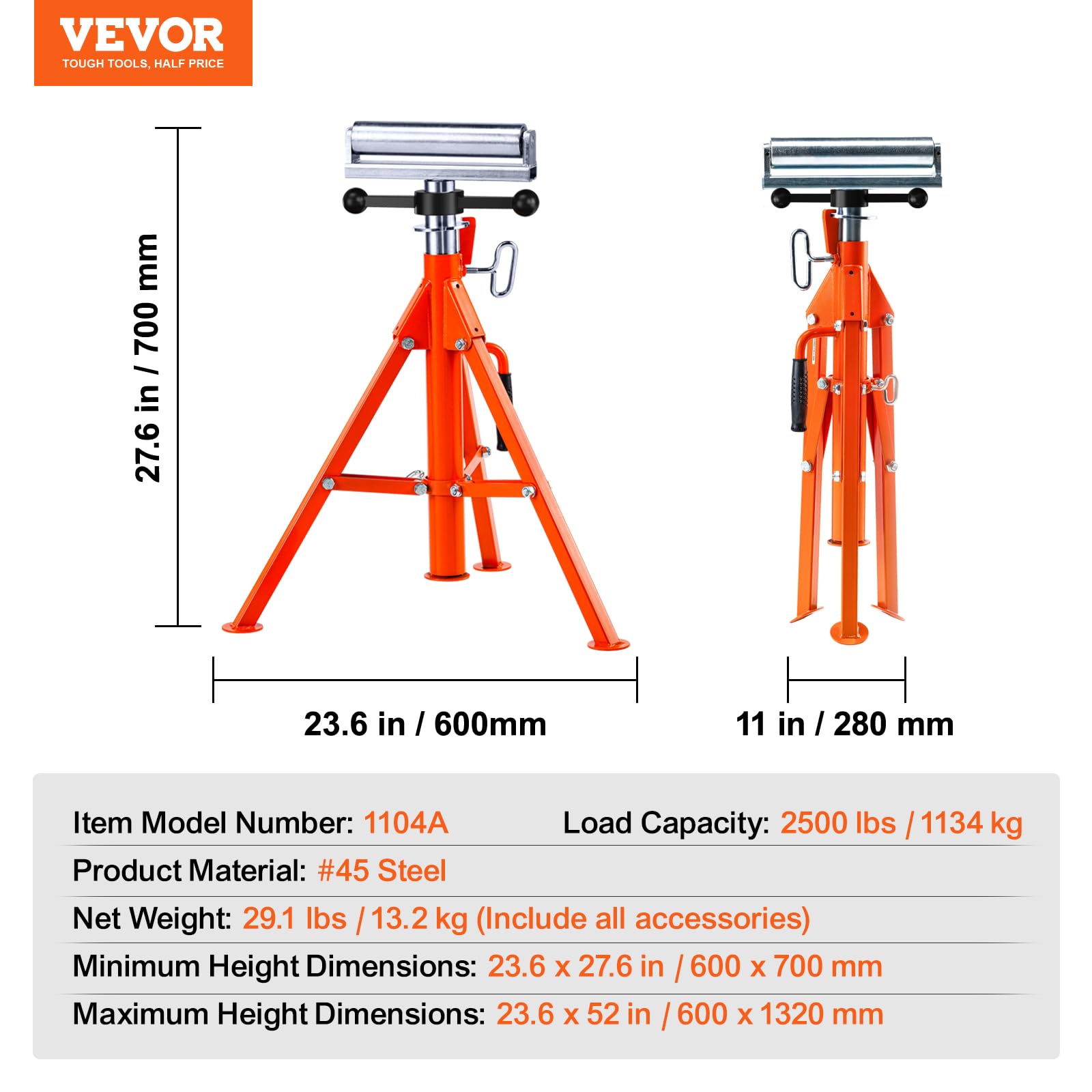

The VEVOR Roller Stand is a heavy-duty tool stand designed to support loads up to 2500 lbs. With an adjustable height range of 28 to 52 inches, it caters to various applications in woodworking and metalworking. Crafted from durable #45 steel, this foldable stand ensures longevity and easy storage, making it an essential addition to any workshop.

| Manufacturer | VEVOR |

| UPC | 197988213857 |

| Part Number | Roller Stand 2500 LBS |

| Item Weight | 29.1 pounds |

| Product Dimensions | 23.6 x 23.6 x 52 inches |

| Item model number | 1104A |

| Style | Heavy Duty Roller Stand |

| Power Source | hand_powered |

| Item Package Quantity | 1 |

| Included Components | 1 x Roller Stand |

| Batteries Required? | No |

E**T

REALLY strong. Excellent base stability, but the roller head annoyingly swivels when it shouldn't.

This would easily be a home run product, if the roller head didn't swivel freely in the stand base. Hence only 3 stars for stability, as if the roller swivels 90 degrees in the base under load, you could have a Very Bad Day. The easiest fix for that I've come up with is to use a worm clamp to hold some 3/4" x 3/4" x 1/8" steel angle to the base, and then use another worm clamp to hold the acme threaded rod to the angle. (It should be apparent that the legs of the angle should straddle the central tube of the base, as well as the acme threaded rod.) It doesn't take much to keep the head from swiveling, but it's important.That gripe aside (and you shouldn't dismiss it out of hand), these are extremely strong stands, and the tripod bases are extremely stable. These are just SO much stronger than those cheap stands that are made of thin square tubing and have pinch-type height adjustments, that there is just NO comparison. Yes, they cost 2x as much, and they are worth it if you are, for example, feeding heavy wood slabs into a drum sander or table saw. The pinch height adjustment stands just will NOT support heavy.One huge caveat here-- I just didn't trust the friction collar that enables you to raise the tube in the stand base, which is how Vevor claims the range of useful heights for these stands, under their claimed 2500# loads. Heck, I wouldn't trust that friction collar (and associated set screw) under 250# load. What I did (and it has worked perfectly under load) was to go to my local remnant steel vendor and buy 10' of 1.75" OD x 1.5" ID steel tubing, and cut it to various lengths such that each could just sit at the bottom of the stand, while providing bearing surfaces for the nut on the acme threaded tang of the roller head. Now I'm in Tall Cotton (as opposed to Deep Kimchee), able to support many hundreds of pounds of load at any height up to 72" on a fully adjustable stand with 5 self-made tube inserts of different lengths (plus the one that came with the stand.) One of those 5 self-made tube inserts was 6" long, which I could add under any of the longer ones, which made all of the longer ones (cut in 1' increments longer than the tube provided with the stand) able to cover 12" of height adjustment, given the length of the stand's acme threaded rod.One other point. I chatted with a Vevor representative, asking if they separately sold the other "heads" that they sell with the same style base. That includes a 4-ball V-shaped roller head, a plain V-shaped head, and two other types. (I was thinking to improve the versatility of the base at less cost than buying the other styles of complete stands.) Nope, no can do. (Product suggestion, Vevor!) But you know what? You can buy acme threaded rod and acme nuts (McMaster-Carr, if you want to open your wallet wide), and weld a flat or a V-shaped steel top to it-- whatever floats your boat (or wood slab, or large diameter pipe, etc.) Note that the ID of the tube that comes with this stand is only 1.495", so you'd need to but 1-3/8" OD acme threaded rod to work with that. The nominally 1.5" ID DOM (aka "seamless") tubing I bought has an ID of 1.553", so I could use 1.5" OD acme threaded rod. But if you get welded seam 1.5" ID tubing, you will want to go for the 1-3/8" OD acme threads, or you will have to bore the tubing to knock down the internal weld bead. (Welded seam steel tubing is MUCH less expensive than DOM, and plenty strong enough for this application, but I tend to overkill everything. Just don't cheap out and buy thin wall tubing-- that could collapse in bending, even if it would never collapse in compression.)Is this stand worth the money, given all I've written about above? Yep. Can you make it MUCH better with some remnant steel and minor sweat equity investment? Oh, Hell yeah. Can you improve its versatility with some [fairly costly] acme threaded rod and nuts? That's my working theory, but validation is still TBD.

R**N

Works great

The best I've ever had

C**K

Stand

Unable to keep the roller head from swiveling sideways while using.

T**B

No ears on adjusting nut

Different from other pipe stands. The adjuster has no wings and no welded on washer. You can’t pick up on the head to adjust it just comes off in your hand. Also not having a way to stop the threaded rod from spinning makes it pretty useless.

A**R

Good solid stands with great hight adjustment

needs to have a jam nut or system to lock rollers in place.

J**M

Serious Design Flaw

As pointed out in the picture, there should be a clamping screw to hold the top adjusting screw from turning like the one at the top of the orange section. Like it is, as soon as something touches the roller it just moves away. There is a hole on one end of the pipe that the adjusting screw slides into, and if there was a nut welded there with a pinch bolt like the one at the top of the orange support, the problem would be solved. I suspect that whoever manufactured these just missed this step in the process. When I mentioned this to Vevor support, they just basically said, it is what it is. This is why it gets one star from me. It is a very sturdy and reasonably price stand but useless unless modified. So, if you are not able to make this modification, I would suggest you look elsewhere.

M**Y

The roller head moves

I had to use a tap and add a bolt to stop the roller head from turning. There's a hole already there on the shaft right below the roller head.

Trustpilot

1 month ago

2 weeks ago